Quality. Service. Productivity.

These are the values that have propelled REO Plastics for over 60 years, and they’ll take us into the next 60 and beyond. Our commitment to continuous improvement has led to offering sustainable solutions and developing new partnerships to better serve our customers. Some things never change, like our on-time delivery.

The plastic parts we mold may look humble, but they help do great things. They make important everyday activities that people rely on possible — delivering clean drinking water, connecting people, and powering business.

The part you need doesn’t exist yet? We’ll develop it for you. Need custom tools? We’ve got you covered.

Whether you need a highly complex part or high volumes delivered on a set schedule, we can accommodate your unique needs. We take pride in developing long-term partnerships with our customers that help drive their business success.

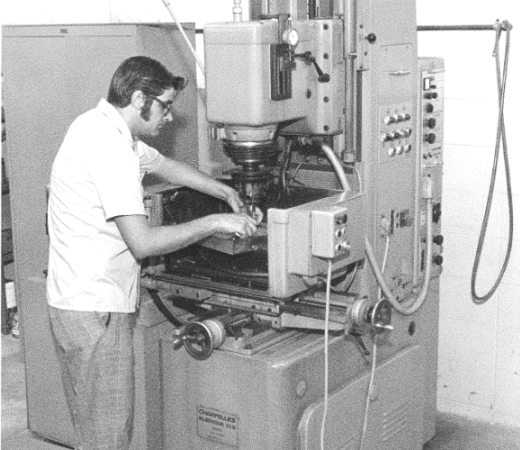

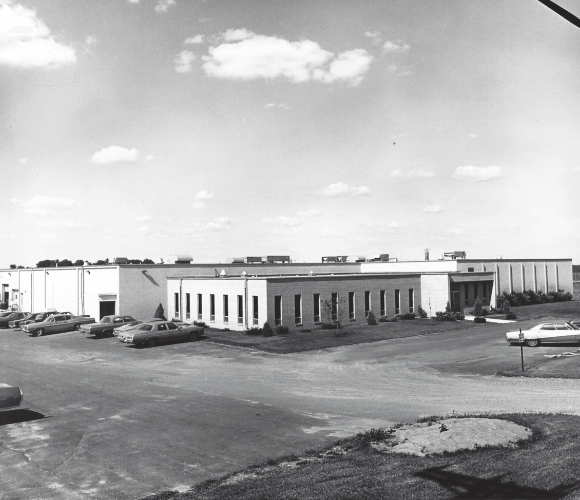

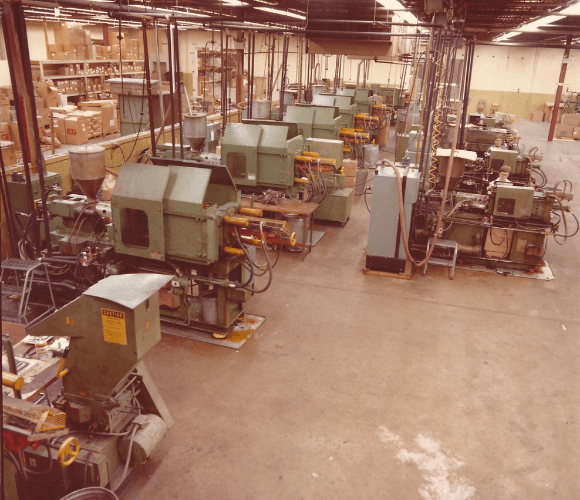

The Beginning of REO Plastics

The REO Team

Leadership Team

REO Customer Service

We consistently focus on customer satisfaction and guarantee the following to help support you and ensure quality results:

- Electronic order entry

- Real-time production monitoring

- Min/max inventory levels

- Short lead times

- Kanban/JIT shipments

- Domestic and overseas tooling

- Flexible, resourceful solutions

- Quality assurance testing