Plastic Injection Molding as an Alternative Fabrication Method

If you are looking for an alternative to traditional fabrication and manufacturing methods, plastic injection molding may be the answer. This method of manufacturing is well-suited for large-scale production and can be used to create a variety of objects and products. Injection molding is also faster and more efficient than other methods, making it an attractive option for businesses and industries. Let’s explore when you should utilize plastic injection molding and what advantages it has.

What is Plastic Injection Molding?

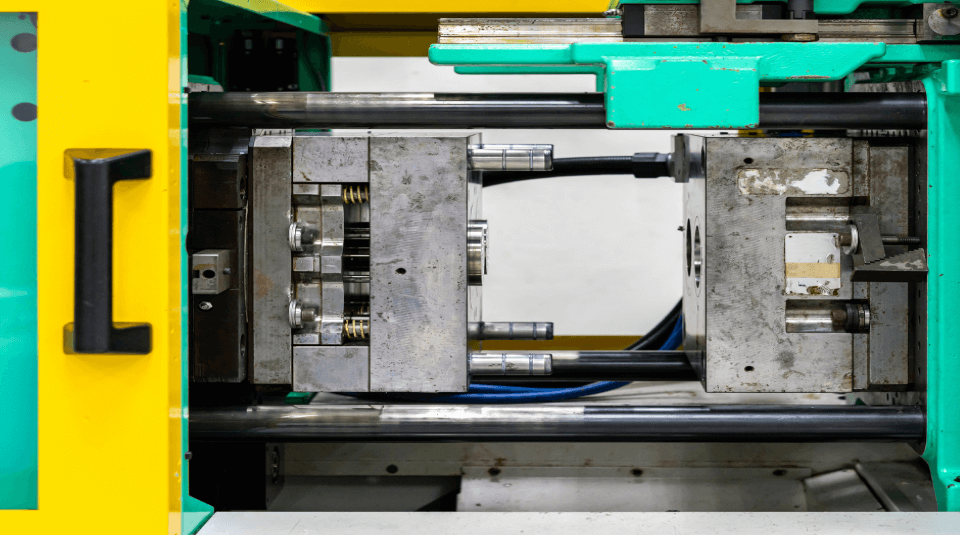

Plastic injection molding is a process that creates three-dimensional parts by injecting molten plastic into a mold.

This process is often used for mass production because it is fast and efficient. Injection molding is also extremely versatile–it can create parts of various sizes, shapes, and colors.

How Does Plastic Injection Molding Work?

The injection molding process begins with melting the plastic down into a liquid form. Once the plastic is in liquid form, it is injected into the mold where it cools and hardens to the shape of the mold.

When Should You Use Plastic Injection Molding?

Plastic injection molding is a great option for mass production or when you need to create complex, three-dimensional parts. It is also a good choice when you need parts that are strong and durable.

What are the Advantages of a Plastic Injection Mold for Fabrication?

The advantages of this process include its ability to create complex shapes, its high production rates, and its low labor costs. In addition, plastic injection molding is a versatile process that can be used to create parts for a variety of industries, including the automotive, electronics, and medical industries.

How to Pick the Right Fabrication Method for You

When it comes to selecting a plastic fabrication method, product functionality and simplicity of manufacturing are important factors to consider. Some methods aren’t suitable for fabricating certain types of plastic, so they may not be useful for your project. Other things to consider include:

- The quantity, size, and function of the finished item

- The tolerance requirements of the item

- How the item will be used or what it will be used for

- What sort of surface finish is required

- Cost and manufacturability

Be sure to also think about what types of machines and processes will be needed to create your product. This can help you determine which plastic fabrication method is right for you.

Is Plastic Injection Right for Your Product?

To learn more about plastic injection molding and whether it is the right method for your business, contact REO Plastics today!